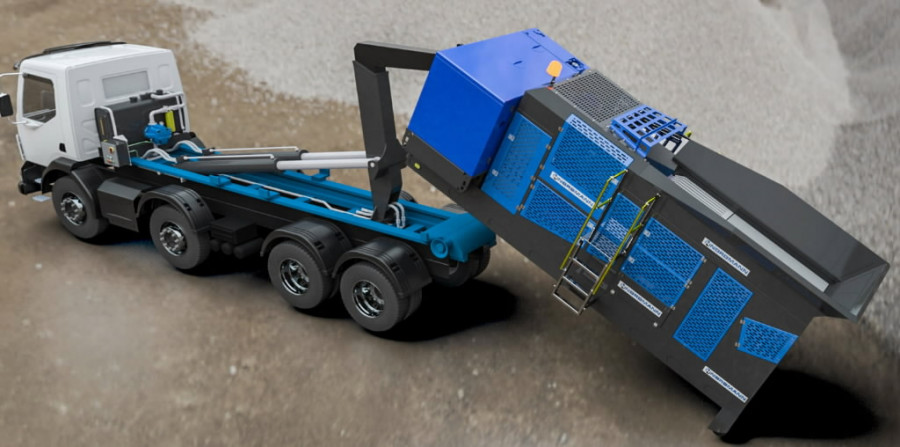

Technical specificationsNordmann jaw crushers are designed for the small quarry and recycling customer and are normally customer owned or hired from rental parks.

The chassis is built to suit ANSI, DIN or CHEM standard hooklift trucks.

We have a design incorporating 700x500 jaw (28"x20"), vibrating grizzly feeder, discharge conveyor and on board Diesel generator. (Dual power as standard)

The design is compact, with all the necessary access and clearances needed and is easy to operate.

It is especially suited where space on site is very restricted and is also an ideal rental tool.

With low running and wear costs, the Nordmann K-750 offers a viable alternative to impact crushing or shredding in demolition material.

K-750 jaw crusher harnesses the power of the on-board Diesel electric generator to crush 0-400mm rock, concrete and brick at typically 50-100tph.*

*Capacities achieved determined by feed material, method & desired product

The chassis is built to suit ANSI, DIN or CHEM standard hooklift trucks.

We have a design incorporating 700x500 jaw (28"x20"), vibrating grizzly feeder, discharge conveyor and on board Diesel generator. (Dual power as standard)

The design is compact, with all the necessary access and clearances needed and is easy to operate.

It is especially suited where space on site is very restricted and is also an ideal rental tool.

With low running and wear costs, the Nordmann K-750 offers a viable alternative to impact crushing or shredding in demolition material.

K-750 jaw crusher harnesses the power of the on-board Diesel electric generator to crush 0-400mm rock, concrete and brick at typically 50-100tph.*

*Capacities achieved determined by feed material, method & desired product